If you want to tell a story that keeps your readers turning pages, you must convince them that perhaps it could be true. Or, at the very least, convince them to suspend their disbelief for the duration of the story. This won’t happen if they spot even small errors in your work. It breaks the spell and they stop reading–something writers strive to discourage–and say “Wait! That’s not right.” And even if they then continue to read, they will be suspicious of everything else you tell them.

In chapter 14, the Temperance chapter of Forging the Blade, the Damian goddess, Brigga, forges a magic sword for Molly, the main character. She uses Molly’s blood to bind her to the blade. As the sword is forged, Molly is also forged into a warrior. I figured that forging a blade would be a perfect metaphor for Temperance. This is a key chapter in the book, and to make it work, the reader must totally believe in the drama of a piece of steel and a teenage girl being forged into sentient, magical weapons. I needed to get the forging process exactly right.

The Internet couldn’t give me all the information I needed to write a believable chapter. It is an amazing tool for gathering bits and pieces and finding out where to get more, but it couldn’t tell me all the tiny, practical details of the process, or what a forge smells like, or how a furnace sounds, or how it feels to hammer a piece of steel into shape. It is always best to write what you know, and I didn’t know squat about forging a blade.

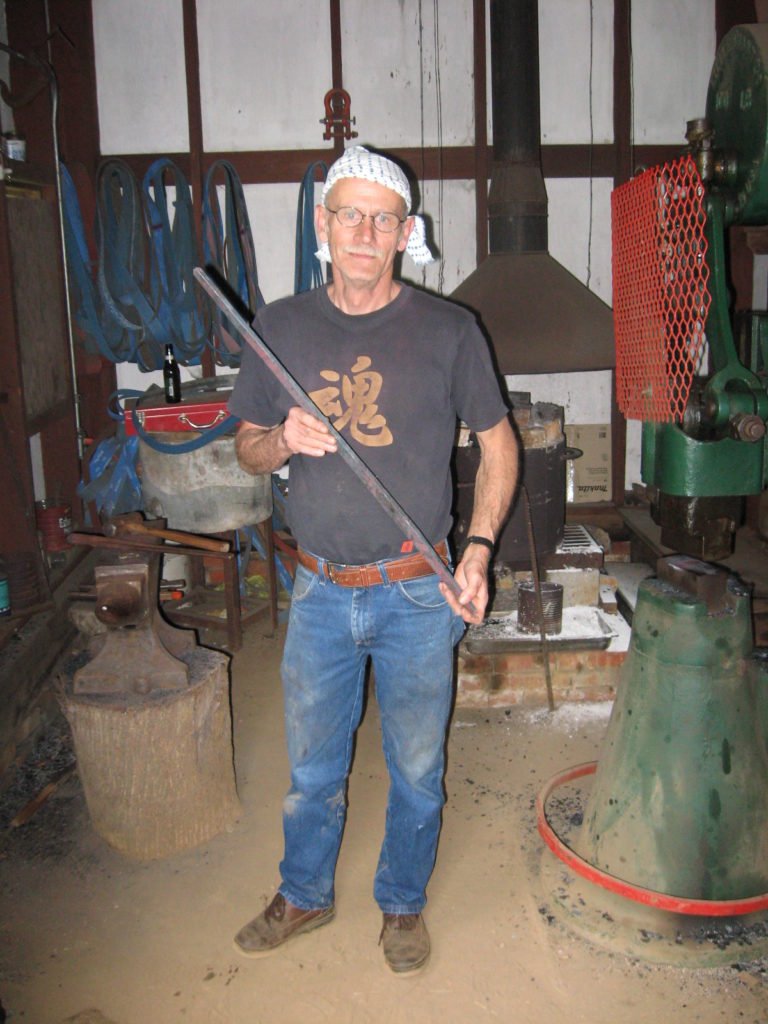

And so it came to pass, that in June of 2007 I drove down the Oregon Coast Highway to Coquille, Oregon, home of Michael Bell, master swordsmith of Dragonfly Forge. He had agreed to let me watch him forge a katana, which is a Japanese sword, and exactly the kind of weapon I wanted Molly to have.

The Bell family home and Dragonfly Forge are tucked up in the hills between Bandon and Coquille, Oregon. My first morning there I sat at their kitchen table, drinking tea in front of a wood-burning stove and listening while Michael described the difference between iron and steel and the changes a blade goes through during its forging—in other words, a crash course on metallurgy. Michael is a slender, soft-spoken man, not at all what you think of when you think of a blacksmith. He was also very patient with all my questions.* After he was satisfied that I had the basics down, we headed out to the small wooden outbuilding which is Dragonfly Forge. There was nothing fancy about it—dirt floors and well-used, simple equipment—but it exuded a comfortable symmetry. Every tool had its place, and I quickly learned that as soon as you were finished using it, it went back in that place.

Michael admits with no shame whatsoever that he cheats. Traditional swordsmiths use charcoal-fired furnaces and they do the rough shaping of the blade with hammers that are nearly as heavy as sledge hammers. His furnace is gas fired and he uses a trip hammer. He also uses electric grinding wheels.

Instead of folding and refolding the billet of steel before he starts shaping the blade, Michael starts with about a foot of steel cable. The cable is perfect, he says, because it’s made from the highest quality steel available; and, since it’s made of dozens of steel wires twisted into a spiral, he doesn’t have to do all the folding. I like the idea of using cable because the spiral is a potent symbol of life and living. As he shapes the length of cable into the sunobe, or rough sword shape, with the trip hammer the spirals of steel wire are forge welded together. If every weld is not perfect, the sword will be flawed and will probably break at the final quenching.

It took him until late afternoon to finish the sunobe.

The second day Michael did more shaping. First he cut and hammered out the point. Then he hammered in the three planes of the blade.

Two planes, called the Mune, form the top or ridge of the blade, the Shingogi-ji form the sides of the blade, and the Ji form the cutting edge.

Steel is very hard. I know that’s like saying the Grand Canyon is very big, but I didn’t really appreciate how hard it is until I started banging on hot (translate: softened) steel with a three pound hammer. My first enthusiastic blow made a tiny, crescent shaped dent. The master swordsmith pointed out that it did that because I’d hit the steel with the edge of the hammer, not the flat pounding surface. Dents are a no-no. Forging those planes took Michael almost a full day of hammering. I was tired after about ten minutes. When he was finished, the blade looked like a dull, blurry version of a finished katana. He heated the whole blade up to yellow heat and let it cool slowly by the furnace. This process is called tempering. It relaxes the metal and makes it uniform throughout the entire length of the blade.

The third day was for grinding and fine shaping.

When he was satisfied that the blade was perfect, Michael applied the clay in a very specific pattern and let it dry thoroughly. When the sword is heated to yellow hot and quenched in water the clay slows down the cooling. The thicker the clay layer, the slower the cooling. The steel that cools slowly doesn’t develop the large martensite crystals that make the blade brittle enough to hold an edge. It is still strong, but more flexible. The lines of clay that are perpendicular to the cutting edge make stripes of softer steel that act like the discs between our vertebrae. This last step is what allows a katana to hold a strong, razor sharp edge, yet be flexible enough to withstand the strikes of another blade and the forces of cutting through armor, rifle barrels, and torsos.

The final day was for drama. The quenching of a Japanese blade does three things:

It finds the flaws. If the forge welding isn’t perfect or if the architecture of the blade isn’t quite right the temperature extremes will cause the blade to shatter or crack or warp.

It transforms the plain, brittle steel of the blade into a miracle blend of steels so strong and flexible that it can cut through iron or nearly anything else you throw at it.

It accentuates the sweet arc that makes Japanese swords look like they’re ready to float out of your hands.

It ensouls the blade and it becomes some a living entity. Really. Ask any Japanese swordsmith.

Michael’s son, Gabriel, who is also a swordsmith, came out to watch. We fired up the furnace, which soon began to roar in an earnest, breathy sort of way. When it was up to heat we closed the shutters on the forge windows and Michael began to pass the blade rhythmically through the hottest part of the flames, heating it evenly throughout its entire length. The darkened forge reached sauna temperatures, and we watched, mesmerized, as the blade glowed cherry red, then orange, then yellow. When he was satisfied with the color, Michael pulled his creation from the flames and thrust it into a trough of cold river-water, which hissed explosively. The forge went silent, and we stood in awe as the master swordsmith lifted a perfect blade from the water and another being joined us in the forge. The katana had survived its ordeal of fire, brutal blows, and water, becoming strong and beautiful and alive.

This was an even better analogy to the Temperance key than I had imagined. As far as I’m concerned, truth wins out over fiction every time. As storytellers, we should use it whenever possible. The rest of the time we can only strive for a good imitation.

*Any errors or omissions are mine alone. Michael Bell, of course, knows exactly how to forge a katana.